In light of emerging environmental awareness, Corum expects to improve our performance in environmental protection and social values, as well as to achieve the benefits of environmental sustain- ability by incorporating green management and energy conservation plans into our business opera- tions. The Company has introduced the ISO 14001: 2015 environmental management and obtained certificates from third-party accreditation units. In terms of environmental topics such as GHG, energy, air pollution, wastewater discharge, and waste disposal, we will continue to improve our perfor- mance in a bid to minimize environmental impact and damage.

In light of global climate change, the tightening of international carbon management regulations, and the increasing awareness of low-carbon consumption, governments, and enterprises around the world are beginning to place greater emphasis on environmental sustainability. In supporting the government's policy on environmental protection and energy conservation, Corum also sees them as one of the most important action goals in combating climate change. Under the leadership of the Sustainability Committee Chairman Li Pei-Min, the Company's approach to combating climate change is reviewed regularly, and the TCFD framework is applied to identify risks and opportunities. Metrics will be formulated based on the identification outcome to implement goal management in order to mitigate the financial impact of climate change on our operations.

As a Taiwanese firm, one of Corum's most important tasks in minimizing local environmental impact and fostering sustainability is to decrease carbon emissions. According to the current investigation, CO2 is the most significant greenhouse gas (GHG) emitted in Taiwan, accounting for 95.36% of all GHG emissions. In particular, shipping is ranked third (13.61%), and we have proposed three energy conservation campaigns.

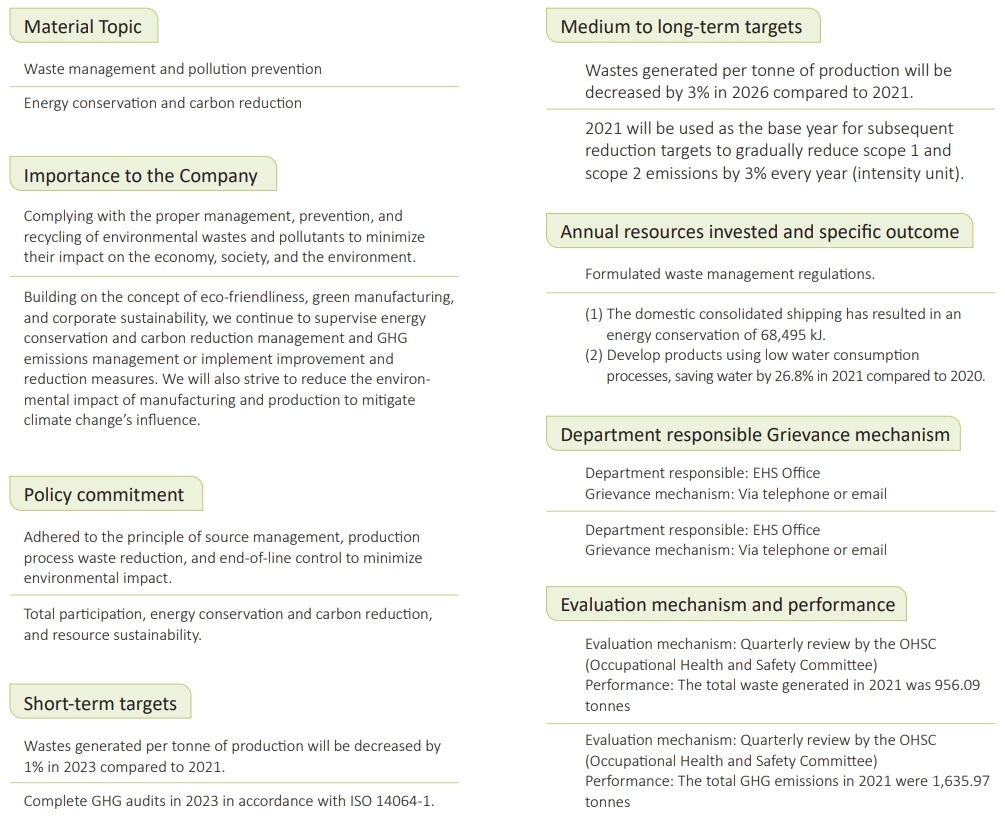

1. Consolidated shipping

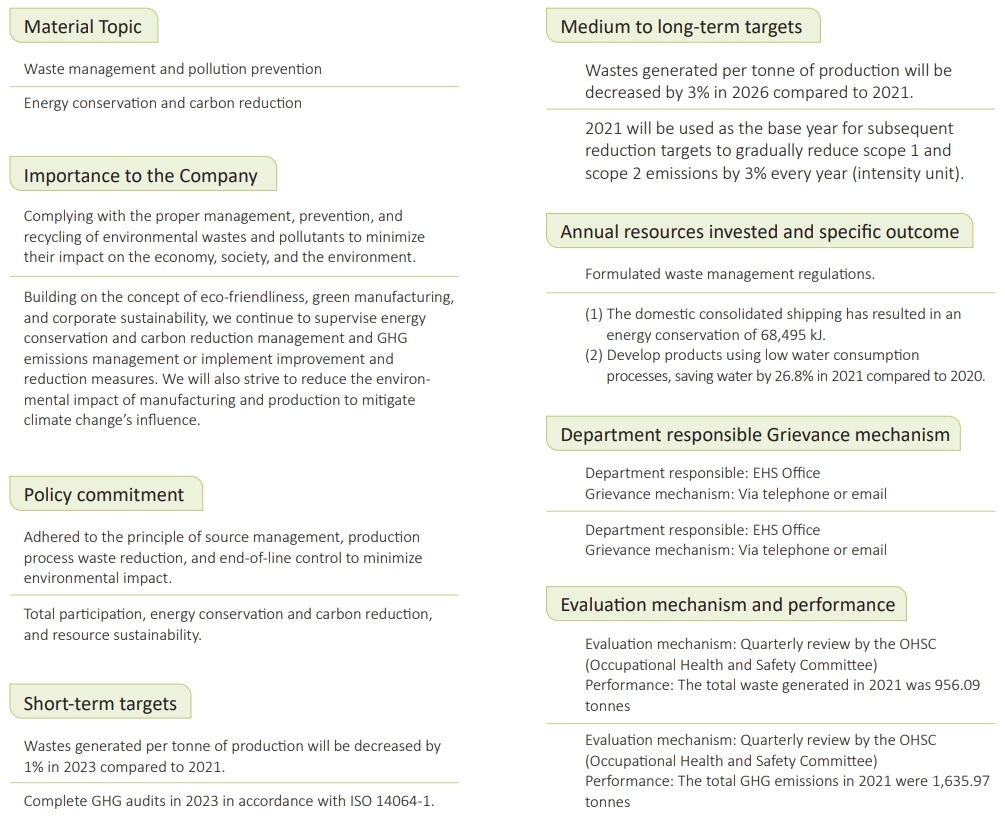

Commitment: We have tallied the customers with more than 14 shipments in 2021 to persuade them to consolidate their orders by regulating the frequency of the shipment of their goods. The goal is to reduce the number of round trips and mileage driven by trucks, as well as lower the cost of shipping. This is Corum's first step toward realizing green transportation.

Risk management: The Domestic Sales Department communicates with chosen customers to convince them of the importance of consolidated shipping.

2. Energy Consumption Control at the Chiayi Factory

Commitment: The bulk of our energy consumption involves electricity, followed by gas and natural gas. We have installed energy control devices throughout the factory to record energy consumption details and examine variations regularly. The aim is to monitor the latest information at all times to analyze performance.

Risk management: The Chiayi factory controls and keeps a record of all energy consumption; if anomalies are discovered, the cause will be determined to implement improvement measures. Since the factory's GHG emissions are relatively low, simple carbon emissions values are recorded for control purposes.

3. Energy Conservation Campaigns

Commitment: We promote the concept of energy conservation and carbon reduction among our employees so that they can keep a good habit of turning off air conditioners that are not in use. We also support the World Wildlife Fund's "Earth Hour 60+" and "World Water Day", as well as regular- ly organize beach cleanup and Corum Art Promotion Award to evoke people's awareness of global warming and energy conservation.

Risk management: Corum will continue to support climate actions by organizing various energy conservation activities to decrease carbon emissions and energy consumption.

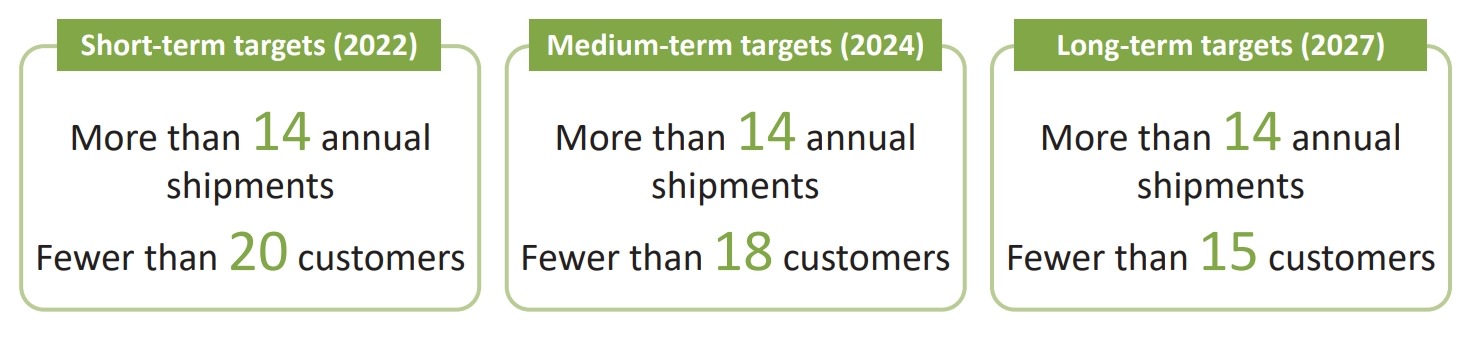

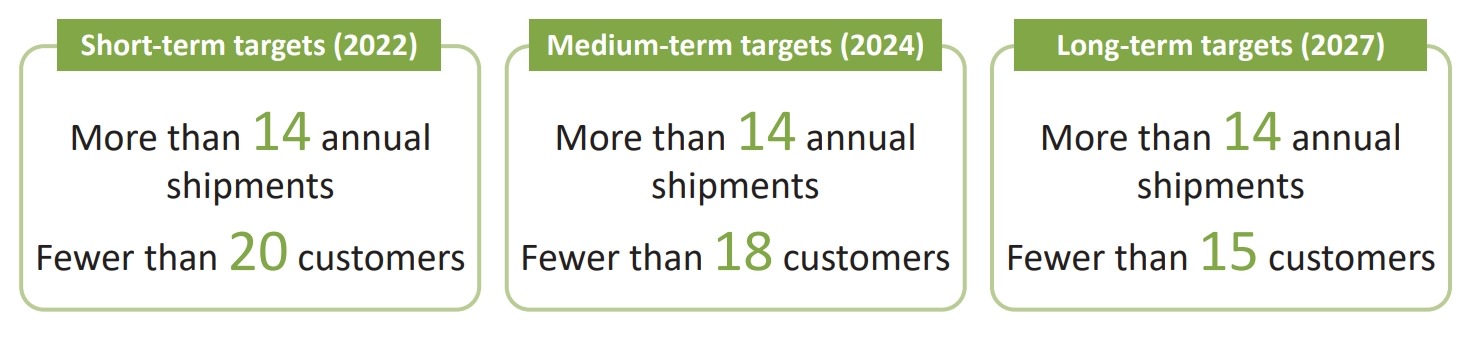

Corum's approach is based on the four major environmental policies:

Energy conservation and carbon reduction

Set yearly carbon reduction goals and implement production process improvements to maximize energy benefits and minimize energy consumption. The office thermostat is set at 26*C because lowering carbon emissions is our duty as corporate citizens.

Waste reduction

Promote waste classification and zero disposable tableware. Install recycling bins to reduce household waste and achieve the objective of waste reduction

Business waste disposal

Business wastes are controlled according to relevant regulations, where wastes are categorized and stored based on their chemical properties before they are disposed of by qualified contractors.

Green procurement

Corum guarantee that our products do not contain substances of very high concern (SVHC) announced by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH). We abide by the Restriction of Hazardous Substances (RoHS)'s environmental protection regulations to promote green procurement management. Apart from demanding our suppliers that their raw materials may not contain harmful substances, the Company never uses raw materials that contain harmful substances during production.

Green product

Corum has established a comprehensive environmental controlled substance management procedure as follows:

We comply with the 12 Principles of Green Chemistry by invest- ing resources in the R&D of green chemical products, which is consistent with the SDGs such as using recycled solvents. Our current recycling rate is 56-60%. We identify and confirm that the Company's products comply with the safety regulations of various markets. Additionally, all our raw material inspections, production processes, intermediate product, and final product inspections are carried out according to the International Council for Harmonisation (ICH) guidelines and GMP regulations. Moreover, our product stability monitoring and testing have been verified. In 2021, Corum's products did not violate any product and safety regulations.

Emergency response

Corum's Chiayi factory is equipped with an emergency response plan and an emergency response team. The team will respond to an exigent situation immediately.

The crisis response education, training, and fire drill are held every six months, where new employees are required to operate the fire extinguisher and train their self-safety management skills with other colleagues through simulation exercises so that they can implement corresponding measures before the disaster escalates and minimize the impact and damage from the crisis.

In 2021, two simulation exercises were conducted according to the emergency response plan, and fire escape and first aid-related training were carried out for our employees in collaboration with firefighters. According to the plan, employees are grouped as follows: on-site commander of various factories, reporting and first aid team, security and communication, evacuation guidance, and safety personnel. This is to allow our colleagues to cope with emergencies and minimize personnel injury and environmental impact.

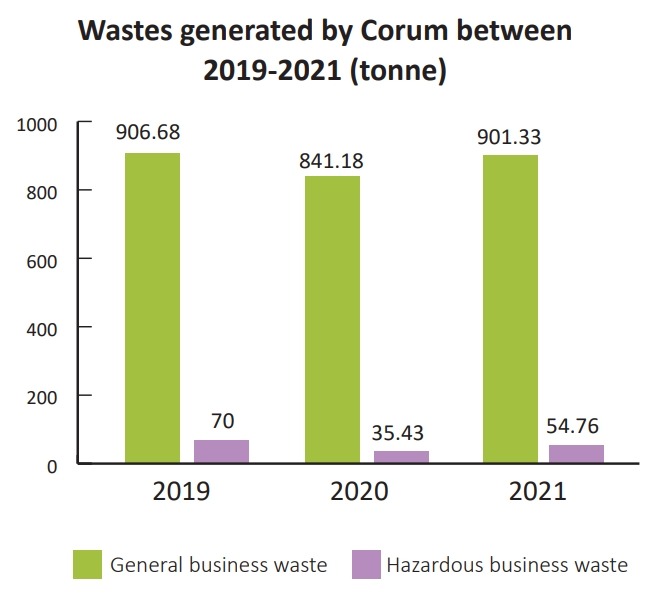

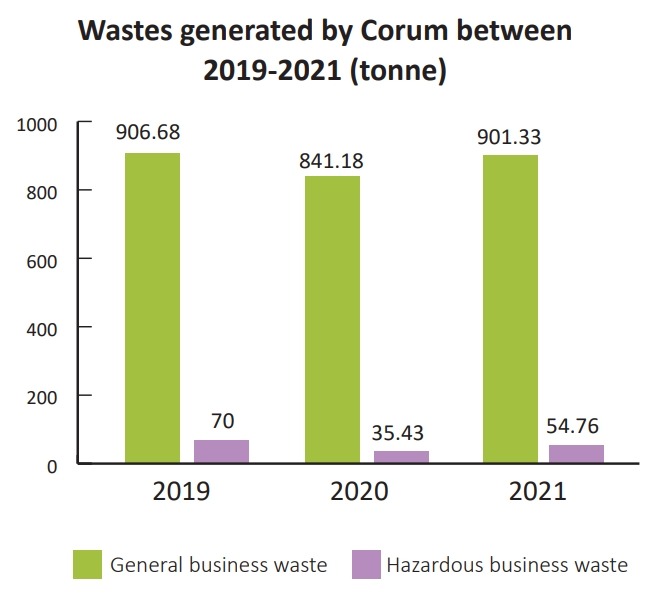

Waste management

All business wastes generated by Corum are recycled and disposed of by qualified contractors.

Waste management emphasizes source reduction followed by waste resource recycling and disposal by contractors in compliance with relevant laws and regulations. Before waste disposal is outsourced to contractors,

twe first categorize, collect, store, and manage wastes in the factory. Suitable waste disposal firms are chosen to clear he waste and declare its final destination in accordance with environmental laws before eventually handing it over to the treatment plant. Currently, all wastes are processed domestically and there is no problem with international processing and waste leakage. Corum's wastes consist of:

1. General business waste

1. D-0299 (waste plastic or its mixture)

2. D-0902 (inorganic sludge)

3. D-1504 (non-hazardous organic waste liquid or waste solvent)

4. D-1506 (waste (sewage) water with a pH of 6.0-9.0)

5. D-2302 (non-halogenated organic waste chemicals)

2. Hazardous Business Wastes

1. C-0301 (the flash point of the waste liquid is less than 60*C (except for alcohol waste with an ethanol volume concentration of less than 24%)

2. C-0299 (other corrosive industrial waste mixtures)

The abovementioned wastes are generated during the production process or by the laboratory, and there are also employees' domestic wastes such as waste wood and waste plastic. When the wastes stored in the factory reach a certain amount, they will be disposed of by EPA-registered and approved contractors. Furthermore, annual audits of the disposal contractors are conducted to ensure the legitimacy of their operations.

In light of emerging environmental awareness, Corum expects to improve our performance in environmental protection and social values, as well as to achieve the benefits of environmental sustain- ability by incorporating green management and energy conservation plans into our business operations. The Company has introduced the ISO 14001: 2015 environmental management and obtained certificates from third-party accreditation units. In terms of environmental topics such as GHG, energy, air pollution, wastewater discharge, and waste disposal, we will continue to improve our performance in a bid to minimize environmental impact and damage.

In light of global climate change, the tightening of international carbon management regulations, and the increasing awareness of low-carbon consumption, governments, and enterprises around the world are beginning to place greater emphasis on environmental sustainability. In supporting the government's policy on environmental protection and energy conservation, Corum also sees them as one of the most important action goals in combating climate change. Under the leadership of the Sustainability Committee Chairman Li Pei-Min, the Company's approach to combating climate change is reviewed regularly, and the TCFD framework is applied to identify risks and opportunities. Metrics will be formulated based on the identification outcome to implement goal management in order to mitigate the financial impact of climate change on our operations.

As a Taiwanese firm, one of Corum's most important tasks in minimizing local environmental impact and fostering sustainability is to decrease carbon emissions. According to the current investigation, CO2 is the most significant greenhouse gas (GHG) emitted in Taiwan, accounting for 95.36% of all GHG emissions. In particular, shipping is ranked third (13.61%), and we have proposed three energy conservation campaigns.

1. Consolidated shipping

Commitment: We have tallied the customers with more than 14 shipments in 2021 to persuade them to consolidate their orders by regulating the frequency of the shipment of their goods. The goal is to reduce the number of round trips and mileage driven by trucks, as well as lower the cost of shipping. This is Corum's first step toward realizing green transportation.

Risk management: The Domestic Sales Department communicates with chosen customers to convince them of the importance of consolidated shipping.

2. Energy Consumption Control at the Chiayi Factory

Commitment: The bulk of our energy consumption involves electricity, followed by gas and natural gas. We have installed energy control devices throughout the factory to record energy consumption details and examine variations regularly. The aim is to monitor the latest information at all times to analyze performance.

Risk management: The Chiayi factory controls and keeps a record of all energy consumption; if anomalies are discovered, the cause will be determined to implement improvement measures. Since the factory's GHG emissions are relatively low, simple carbon emissions values are recorded for control purposes.

3. Energy Conservation Campaigns

Commitment: We promote the concept of energy conservation and carbon reduction among our employees so that they can keep a good habit of turning off air conditioners that are not in use. We also support the World Wildlife Fund's "Earth Hour 60+" and "World Water Day", as well as regular- ly organize beach cleanup and Corum Art Promotion Award to evoke people's awareness of global warming and energy conservation.

Risk management: Corum will continue to support climate actions by organizing various energy conservation activities to decrease carbon emissions and energy consumption.

Corum's approach is based on the four major environmental policies:

Energy conservation and carbon reduction

Set yearly carbon reduction goals and implement production process improvements to maximize energy benefits and minimize energy consumption. The office thermostat is set at 26*C because lowering carbon emissions is our duty as corporate citizens.

Waste reduction

Promote waste classification and zero disposable tableware. Install recycling bins to reduce household waste and achieve the objective of waste reduction

Business waste disposal

Business wastes are controlled according to relevant regulations, where wastes are categorized and stored based on their chemical properties before they are disposed of by qualified contractors.

Green procurement

Corum guarantee that our products do not contain substances of very high concern (SVHC) announced by the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH). We abide by the Restriction of Hazardous Substances (RoHS)'s environmental protection regulations to promote green procurement management. Apart from demanding our suppliers that their raw materials may not contain harmful substances, the Company never uses raw materials that contain harmful substances during production.

Green product

Corum has established a comprehensive environmental controlled substance management procedure as follows:

We comply with the 12 Principles of Green Chemistry by investing resources in the R&D of green chemical products, which is consistent with the SDGs such as using recycled solvents. Our current recycling rate is 56-60%. We identify and confirm that the Company's products comply with the safety regulations of various markets. Additionally, all our raw material inspections, production processes, intermediate product, and final product inspections are carried out according to the International Council for Harmonisation (ICH) guidelines and GMP regulations. Moreover, our product stability monitoring and testing have been verified. In 2021, Corum's products did not violate any product and safety regulations.

Emergency response

Corum's Chiayi factory is equipped with an emergency response plan and an emergency response team. The team will respond to an exigent situation immediately.

The crisis response education, training, and fire drill are held every six months, where new employees are required to operate the fire extinguisher and train their self-safety management skills with other colleagues through simulation exercises so that they can implement corresponding measures before the disaster escalates and minimize the impact and damage from the crisis.

In 2021, two simulation exercises were conducted according to the emergency response plan, and fire escape and first aid-related training were carried out for our employees in collaboration with firefighters. According to the plan, employees are grouped as follows: on-site commander of various factories, reporting and first aid team, security and communication, evacuation guidance, and safety personnel. This is to allow our colleagues to cope with emergencies and minimize personnel injury and environmental impact.

Waste management

All business wastes generated by Corum are recycled and disposed of by qualified contractors.

Waste management emphasizes source reduction followed by waste resource recycling and disposal by contractors in compliance with relevant laws and regulations. Before waste disposal is outsourced to contractors, twe first categorize, collect, store, and manage wastes in the factory. Suitable waste disposal firms are chosen to clear he waste and declare its final destination in accordance with environmental laws before eventually handing it over to the treatment plant. Currently, all wastes are processed domestically and there is no problem with international processing and waste leakage. Corum's wastes consist of:

1. General business waste

1. D-0299 (waste plastic or its mixture)

2. D-0902 (inorganic sludge)

3. D-1504 (non-hazardous organic waste liquid or waste solvent)

4. D-1506 (waste (sewage) water with a pH of 6.0-9.0)

5. D-2302 (non-halogenated organic waste chemicals)

2. Hazardous Business Wastes

1. C-0301 (the flash point of the waste liquid is less than 60*C (except for alcohol waste with an ethanol volume concentration of less than 24%)

2. C-0299 (other corrosive industrial waste mixtures)

The abovementioned wastes are generated during the production process or by the laboratory, and there are also employees' domestic wastes such as waste wood and waste plastic. When the wastes stored in the factory reach a certain amount, they will be disposed of by EPA-registered and approved contractors. Furthermore, annual audits of the disposal contractors are conducted to ensure the legitimacy of their operations.